Benefits of Modular Plastic Conveyor Belts

What Is a Plastic Belt Conveyor?

Plastic belt conveyors, also referred to as plastic chain conveyors, are designed to transport various products ranging from lightweight packaged or unpackaged materials to heavy loads that require additional support. These conveyors can feature a steel or aluminum base, simplifying installation processes.

What Are Modular Belt Conveyors?

Modular plastic belt conveyors are widely used in numerous industrial and manufacturing settings.

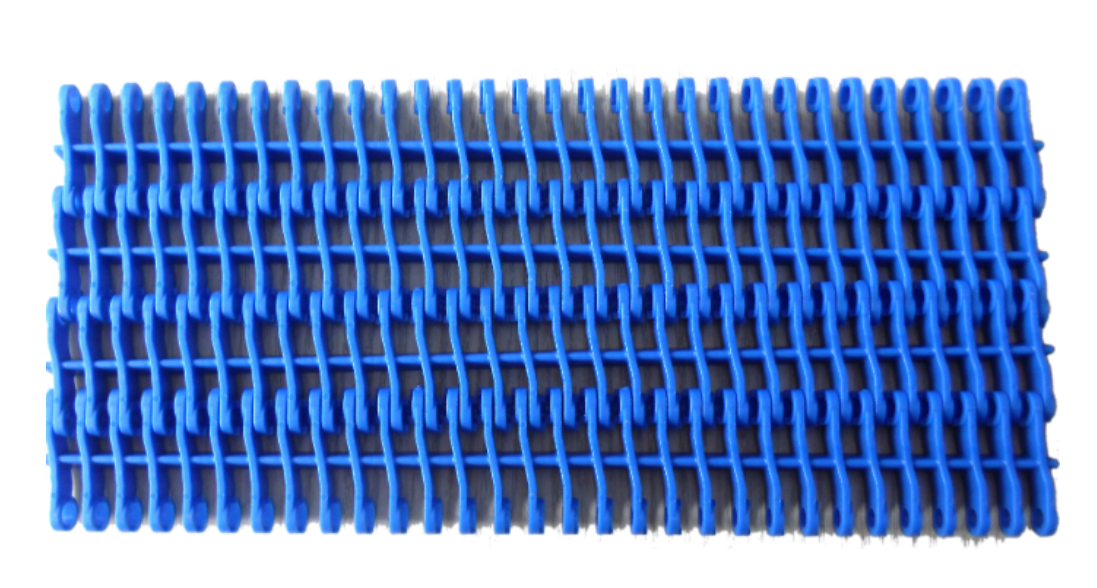

These belts consist of modular plastic or metal sections linked together to create a belt. This design is robust and durable, allowing for easy customization to meet various operational requirements.

Modular belt conveyors can transport small components, large items, and much more. They are often employed in assembly lines and diverse production processes.

Additionally, modular belt conveyors can be reconfigured easily, enabling adjustments to the direction or length as needed.

Numerous types of modular belt conveyors are available today, including:

Gravity Roller Conveyors: These systems utilize gravity to move materials downstream. They are commonly found in assembly lines and production processes that require quick and efficient item movement.

Powered Roller Conveyors: These conveyors employ electric motors to propel rollers, facilitating material transportation. They are suitable for heavier applications, such as moving bulky boxes or packages.

Chain Conveyors: Chain conveyors operate similarly to belt conveyors but utilize chains to transport materials. These are generally used in heavy-duty contexts for large or hefty objects.

Benefits of Modular Plastic Conveyor Belts

Plastic modular belt conveyors feature hinged, interlocking plastic segments instead of traditional flat belts. This innovative design permits the replacement of damaged segments, reducing downtime and costs associated with belt replacements. Consequently, plastic modular belt conveyors enhance production efficiency while minimizing expenses.

Durability and Longevity

The durability of modular plastic conveyor belts is a significant advantage. Constructed from high-quality plastic modules, these belts can endure harsh operating conditions. Unlike fabric or metal belts that may deteriorate or corrode, modular plastic belts resist abrasion, chemicals, oils, and moisture. This characteristic makes them suitable for industries that experience heavy-duty handling and challenging environments.

The extended lifespan of these belts decreases the need for frequent replacements, providing a cost-effective long-term solution. Their modular nature allows for the replacement of only the damaged section without needing to replace the entire system, further extending longevity and reducing downtime.

Customization and Flexibility

Modular plastic conveyor belts allow for significant customization and flexibility, making them adaptable for various applications. They can be designed in different sizes, shapes, and materials to fit specific operational requirements. Whether for food processing, package handling, or automotive assembly, modular plastic belts can be tailored to the unique needs of each task.

The modular design enables easy adjustments and modifications. Conveyor systems can be expanded, shortened, or reconfigured as needed, ensuring adaptability to shifting production lines or workflows. This flexibility allows businesses to upgrade or modify their conveyor systems without investing in entirely new infrastructure.

Easy Maintenance and Repair

A key benefit of modular plastic conveyor belts is their straightforward maintenance and repair. Traditional conveyor belts, such as fabric or metal versions, can be costly and difficult to repair. In contrast, modular plastic belts can be serviced with ease, as individual modules can be replaced or repaired independently without affecting the entire system.

If a malfunction occurs, only the damaged section requires replacement. This efficient repair process minimizes downtime, lowers maintenance costs, and allows for quick resumption of conveyor operation. Many modular plastic belts are designed with easily removable sections, facilitating convenient cleaning and maintenance routines, critical in industries such as food processing where hygiene is essential.

Enhanced Safety Features

Safety is a vital consideration in any manufacturing or industrial environment, and modular plastic conveyor belts incorporate features that improve worker safety. These belts have smooth surfaces that reduce product damage, spills, and accidents. Additionally, they use low-friction designs that prevent materials from slipping or causing unnecessary wear and tear on the belt.

Modular plastic belts may also include sideguards, cleats, or guardrails to avert items from falling off the conveyor, enhancing safety during transport. Some models are designed to be antistatic, preventing static buildup that can pose hazards in certain industries like electronics manufacturing or when handling flammable materials.

Hygienic and Easy to Clean

Modular plastic conveyor belts are especially suitable for industries with stringent hygiene standards, such as food and pharmaceuticals. These belts feature smooth surfaces and minimal crevices, making them more straightforward to clean and sanitize than traditional belts. The modular design facilitates quick disassembly, allowing easier access to all parts of the conveyor belt for thorough cleaning.

Furthermore, plastic belts are less likely to retain bacteria or contaminants, leading to a cleaner and more hygienic work environment. The ability to clean the belts efficiently between production runs helps to prevent cross-contamination and ensures compliance with food safety regulations, such as those established by the FDA and other industry-specific standards.

Conclusion

Modular plastic conveyor belts present numerous advantages that make them a highly suitable choice for businesses across various industries. Their durability, flexibility, and customizability cater to the unique needs of any application, while their ease of maintenance, enhanced safety features, and energy efficiency position them as a reliable and cost-effective solution for long-term usage.

188

0

0

Comments

All Comments (0)